Manufacturing Cold Pour Sealant since 1982

Data Chart | Joint and Crack Sealing Basics | Cold Pour/Hot Pour Comparison

Product Information Data Chart

|

Product ALT |

Product Name | Coverage Per Gallon | Application Methods | Reduction/ Clean-Up |

Drying Time | Color |

| 651 | Flex Crac™ | Up to 80 Linear Ft. ½" X ½" |

Manually or Crack Sealing Pump | None Water |

30 min. | Black |

|

649 652 |

Up to 20 ft.² ¼" Depth |

Spray, Roll or Squeegee Squeegee |

None Water |

30 min. | Black | |

| 653 | Trowel Flex Crac™ | Up to 20 ft.² ¼" Depth |

Squeegee Trowel | None Water |

30 min. | Black |

| 654 | Super Flex® | Up to 80 Linear Ft. ½" X ½" |

Manually or Crack Sealing Pump | None Water |

30 min. | Black |

| 655 | Duraflex® | Up to 80 Linear Ft. ½" X ½" |

Manually or Crack Sealing Pump | None Water |

30 min. | Black |

| 671 | Flex Crete™ | Up to 80 Linear Ft. ½" X ½" |

Bulk Caulking Gun or Crack Sealing Pump | None Water |

30 min. | Gray |

Joint and Crack Sealing Basics

|

|

|

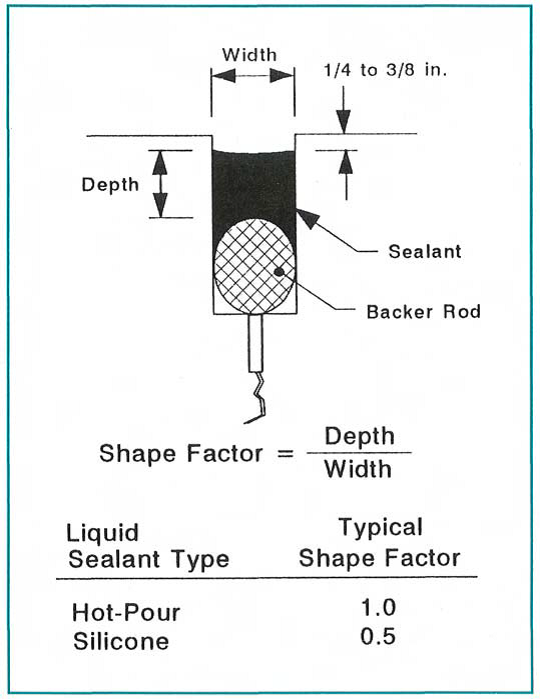

Typical Shape Factor for Sealants - Allstates Coatings' Cold Pour Sealants can have a Shape Factor of up to 1.5 on reservoirs up to 2" (50.8 mm) wide and significantly higher on reservoirs less than 1" (25.4 mm) wide. |

Cold Pour vs. Hot Pour Crack Sealer Comparison

| Cold Pour | - | Hot Pour |

| One component ready to use, stir or circulate 5 min. when using drum pump. | Preparation for Use | Solid must be converted to liquid--requires 2-4 hours. at temperatures around 450°F. |

| Has temperature limitations. Do not apply when surface & ambient temperature is below 45°F. | Application Temp. | Can be applied in cooler temperatures but not when freezing. |

| Up to 80 linear ft. of ½" X ½" cracks. | Coverage Linear Ft. | Up to 80 linear ft. of ½" X ½" cracks. |

| 30-45 minutes. High humidity has dramatic effect on drying. | Drying Time to NO Pick-up | Under 5 minutes. High humidity has dramatic effect on drying & bonding. |

| Can be used on damp surface as long as no standing water. | Reaction to Damp-Wet Surface | Intolerant to any dampness--will return to solid state too quickly to bond to sides of crack. |

| Additional labor cost -0-. Fuel cost per day to run air compressor. | COST-In Addition to Product & Equipment | Labor cost for heat-up and Clean-up per day. Propane cost for heat-up per day. |

| Feasible regardless of job size. | Job Size Feasibility | Only feasible on big jobs in excess of 10,000 L.F. |

| Approximatly 5 drums a day. | Application Rate | Approximately 2160 lbs. or 1 pallet a day of solid material. |

| Drum wt. 550 lbs. less 128.2 lbs. water wt. = drum solids wt. of 421.8 lbs.. 5.12 drums=2160 lbs. solids. | Conversion of 100% Solid Hot Pour to Liquid 55 Gal. | 2160 lbs. hot pour solids=wt. of 1 pallet of 36 boxes @ 60 lbs. ea. Converts to 5.12 drums. |

| $0 - $2,500 | Equipment Cost for Application | $2,000 to $50,000 |

| 5 minutes flush with water. | Clean-Up | Can require hours for cool down--clean with solvents. |

| Safest equipment and product that can be made. Absolutely NO risks to user or environment. | Safety | Extremely dangerous to use due to volatility of propane as well as risk of being severely burned by molten product (Propane expands 1700 time its vol. in an explosion.) |

| Meets all E.P.A. emission standards. | V.O.C.'s | Does not meet emission standards. |

Home | Company Profile | Product Line | Pavement Catalog | Crack Sealers | Industrial Coatings | Distributor List